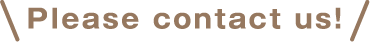

Our made-in-Taiwan presses are designed in Japan and manufactured at our Taiwan factory with engineering, systems and more than 20 years of experience in international production.

You can trust the quality of the equipment designed in Japan.

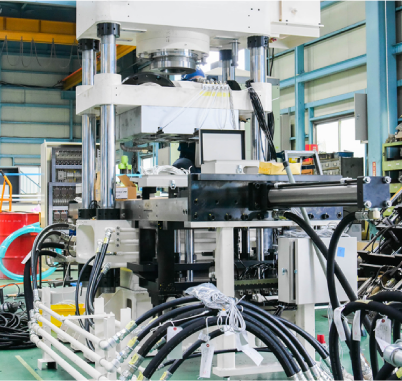

We meet our customers domestically in Japan to determine specifications. Since we handle every stage in-house (with Japanese staff), from the manufacturing of the press to the transportation of the machine, setup operations, maintenance and rebuilding, we can offer consistent support with Japanese staff.

We know that many people worry about the quality of products made overseas, but we have more than 15 years and 500 units of experience with international production. We also have Taiwanese staff in Japan able to communicate in Japanese. This enables us to rapidly respond to inquiries, so we can minimize delays. We have never had a problem that required dispatching a Taiwanese engineer!

Our made-in-Taiwan units are not delivered as-is, but are improved in terms of the mechanical strength and functionality for Japan. We can also manufacture using Japanese components or parts with designated specifications for electrical parts. Select between Japanese, English and Chinese on the operation panel to meet client specifications. The platen (hot surface) dimensions and stroke can also be chosen for your custom application. Additional options include mold memory devices and linear encoders.

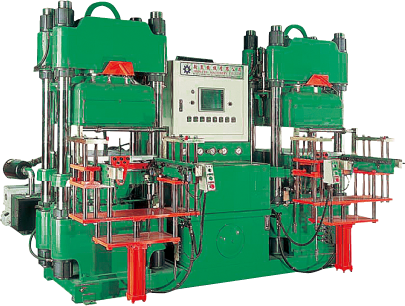

When a press is made, customers can attend the verification on-site in Taiwan. See the equipment yourself before delivery to eliminate risks.

Almost all presses made overseas being sold in Japan are sold by trading companies. Although they are cheap to purchase, it is difficult to get maintenance or modification performed. Iwaki Industry has a comprehensive after-sales maintenance system. Our Japanese staff perform all setup operations, maintenance and rebuilding so you do not need to worry about what will happen after your purchase.